Preserving Our Stained Glass Windows

By now you should have received your pledge form in the mail for the Stained Glass Window

Restoration Project. We’re hoping you will prayerfully consider your response to this request. We and future generations will all reap the benefits of restoring our beautiful stained glass windows. If you haven’t done so already, please complete your pledge form and

return it to the church office.

Here’s a bit of information on how stained glass windows are made. Glass is made by fusing together, at high temperature (about 2500 degrees Fahrenheit), some form of silica such as sand, an alkali such as potash or soda, and lime or lead oxide. The colors in glass are produced by adding a metallic oxide to the mixture. Cobalt is used to produce most shades of blue; chromium and iron oxide produce green colors; yellow and gold are produced using uranium, cadmium sulfide, or titanium; and ruby colored glass is made by adding gold.

Stained glass is still made the same way as it was in the Middle Ages and comes in various forms. For the glass used in leaded glass windows, a lump of the molten glass is caught up at one end of a blowpipe, blown into a cylinder, cut and unrolled into a flattened sheet and cooled. Large manufacturers of stained glass mix the raw materials in huge mixers. The mix is then melted in a modern furnace at 2500 degrees Fahrenheit. Each ingredient must be carefully measured and weighed according to a calculated formula in order to produce the appropriate color. The molten glass is ladled into a machine that rolls the glass into 1/8th inch thick sheets. The sheets are then cooled in a special furnace called an annealing lehr. There are hundreds of colors, tints, and patterns produced as well as a number of different textures.

Though some of the tools to make stained glass windows have been improved, the windows are still hand crafted just as they were centuries ago. The first step involves the artist creating a small scale version of the final design. Accurate measurements, or a template of the actual window openings, are necessary to create the pattern. This pattern is then drawn on paper or cardboard and is the actual size of the spaces that will be filled with glass. From this pattern the cutline and

pattern drawings are made. The cutline drawing is a careful, exact tracing of the leadlines. These leadlines are the outlines of the shapes for patterns to which the glass is to be cut. This drawing serves as the guide for the subsequent placing and binding with lead all of the pieces of glass. The pattern drawing is a carbon copy of the cutline drawing. It is cut along the leadlines with double bladed scissors which, as it passes through the leadlines, cuts away a narrow strip of paper that creates the exact space needed to place the lead caming between the pieces of glass. The pattern drawing is then used to cut the pieces of glass to the desired shape using a diamond or steel wheel.

The next step is glazing. The cutline drawing is placed on a table and marrow strips of wood are nailed down along two edges of the drawing to form a right angle. Long strips of the lead came are placed along the inside of these narrow strips of wood. The piece of glass that is to fit in this right angle is put into place and the came is placed around the exposed edge of this piece. Then the subsequent pieces of glass and each subsequent piece of glass is put in place according to the pattern. The many joints formed by the lead caming are then soldered on both sides. After the

window has been inspected, it is packed in sections and shipped to their destination where they are installed and secured with reinforcing bars.

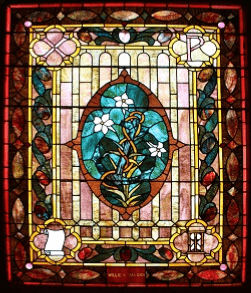

When you’re in church take the time to wander around and look closely at our beautiful stained glass windows. They were made back in 1897, using pretty much the same method described above. They’re great examples of late Victorian stained glass windows, with their intricate designs and wide range of patterns and colors. Look for the various religious symbols that are present. Watch the rainbow of colors and patterns that are formed by the light coming through the windows. These windows are a beautiful part of our church and deserve our care and attention. Thank you for your generous support of this project! Every pledge and donation helps us get closer to our $150,000 goal!

Thank you,

Jim M., Darrel R., &

Paul V.P.